CASE STUDIES

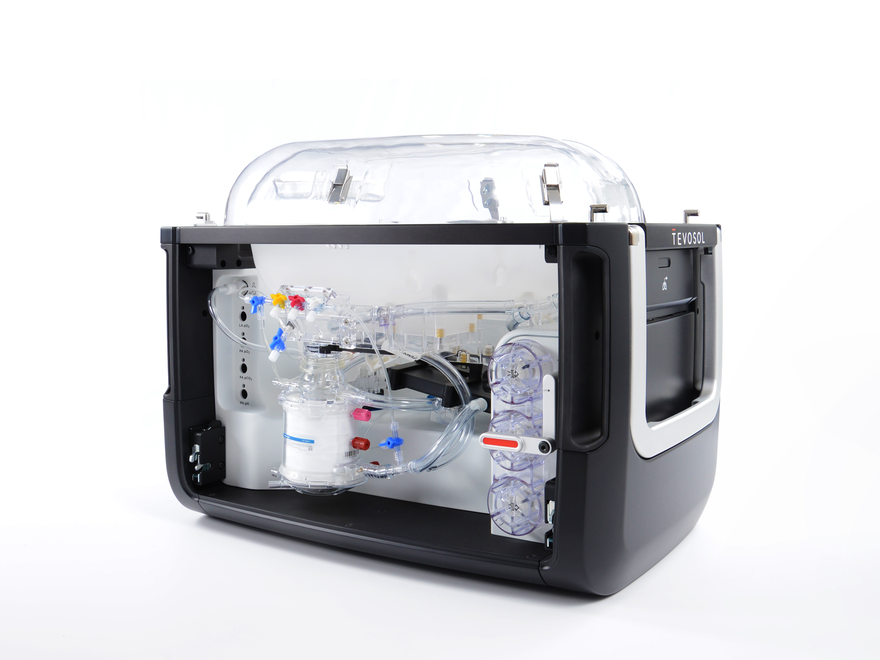

Living Lung

RT collaborated with a notable medical device designer to produce 44 injection molding tools, 200 machine parts and 5 compression tools all within 6 months.

1Bio-compatible & gamma sterilizable plastic components

2Sourcing of medical grade CNC machined plastic

3Compression molding

4Cleaning procedures

1

2

3

4

Water Union Spool

RT Prime manufactured a water spool using plasma welding to achieve superior hardness and abrasion resistance.

1Plasma welding

2Precision machined 316 stainless steel tube. Actual size approx. 5 inches OD

1

2

Precision Die-casting

RT Prime worked with the client to turn a pre-existing fabricated design into a die-casted product while maintaining functionality, precision and strength while achieving significant cost savings.

1Die-cast aluminum

2Post machining and powder coating

1

2

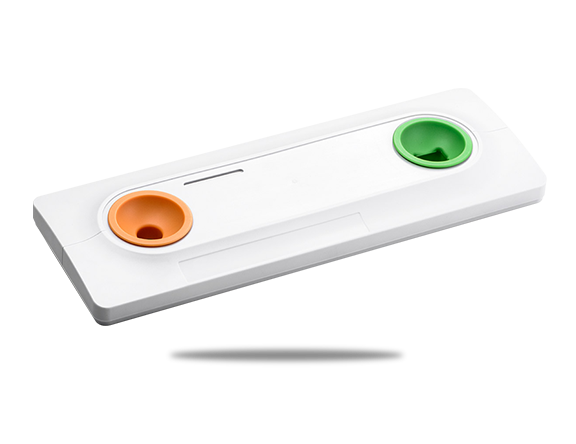

Medical Equipment

Injection moulded product for medical equipment where brand name parts are specified by the client to meet the highest standard. All colours are custom and grey pigment added. RT worked with the customer through tooling design, prototyping, production and delivery.

1Color customized according to unique pantone colour code

2Modified tooling to create a high standard of surface finishing

3Specialized medical grade materials were sourced and purchased by RT

1

2

3

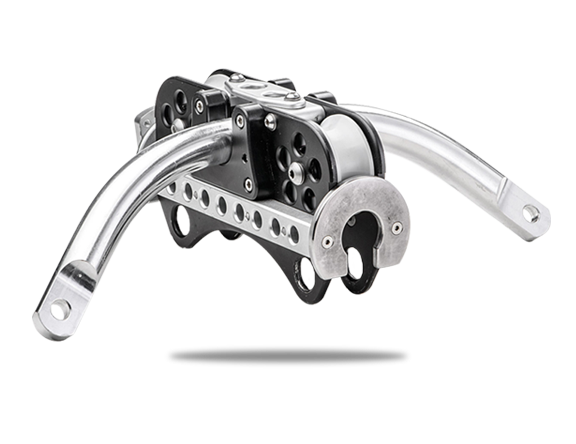

High-Speed Trolly Unit

High-speed trolly unit built for Wildplay Element Parks. RT Prime assisted from initial prototyping to final delivery. All components are supplied and managed by RT Prime to meet all requirements.

1Special polyurethane material procured in the US.

2CNC machined tube – heat treated and tested

3Precision CNC machining and hard coat black anodized

1

2

3

Cart Project

Approximately 200 items were included in the bill of materials, all of which RT Prime procured and managed. We also managed all assembly and shipping of the finished product to the customer.

1Sand casting aluminum base

2Medical Grade casters purchased from Germany

3Brake assembly parts purchased from Japan

4Autobody paint

5Precisions sheet metal

6CNC tube bending

7CNC machining

1

2

3

4

5

6

7