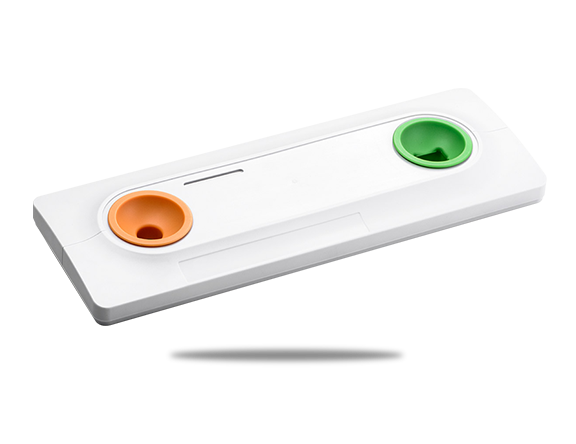

Medical Equipment

RT’s Medical Device Assembly Expertise

A notable medical device manufacturer was struggling to produce their equipment in the three custom colors within budget at low volume...until RT stepped in.

Instead of having to spend $15,000+ in custom-batched resin costs, RT's expertise was put to work. We helped the engineering team specify the color and provided color-matched samples with pricing to save the customer time and money. We simplified the overall process by designing and making the tooling, producing the custom plastic parts with sourced components, and assembling the products ensuring testing standards were followed.

The result? Low-volume medical equipment assembly that was medical-grade, bio-compatible, and came with the travel, inspection, and quality assurance documentation needed for medical use.

Included processes:

- Modified tooling

- Color-customized according to unique pantone colour code

- Special materials specified by the customer which were sourced and purchased

- Met health and safety requirements

- Quality assurance documentation

Continue to learn more about our previous projects by checking out our case studies.